Beo Textile Production

PRECISION MANUFACTURING FOR DEMANDING REQUIREMENTS

We manage every stage of workwear production under one roof from sourcing to final packaging. Full control. Full quality.

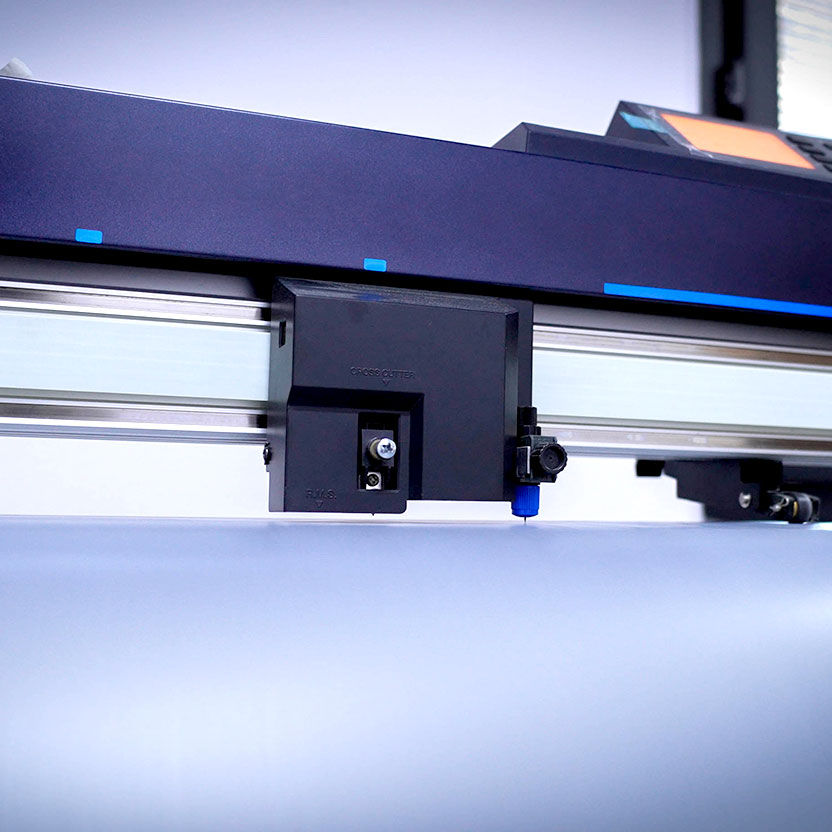

Inhouse Cutting

Automated cutting with latest technology equipment.

Inhouse Heat Sealing

High heat sealing capacity for all kinds of transfer and sublimation prints.

Inhouse Sewing

Automated cutting with latest technology equipment.

Quality Control

At Beo Textile, we uphold strict quality standards throughout every stage of production. From fabric selection to final product delivery, each step is carefully monitored by our experienced quality control team.

Production with the Latest Technology

Durable Fabric and Long Lifespan

Ergonomic Design and Comfort

Precision Manufacturing for Demanding Requirements

Engineered for Every Wash Condition

Custom Made Reflective Design

Compliance with International Standards(CE, ISO, etc.)

BEO TEXTILE

Production Details

At Beo Textile, our production process is not merely about manufacturing textile products; it is also an approach shaped by quality, sustainability and advanced technology. Every stage is carried out with attention to detail and respect for our work.

Industrial Sewing Automation

High-tech machinery for fast, standardised and error-free production.

Fine Craftsmanship and Durability

Products that are both aesthetically pleasing and durable, thanks to special sewing techniques for the fabric.

Controlled Production Stages

Each production line is continuously monitored by quality engineers.

Cutting Workshop

The first step in quality production: precise fabric cutting.

Packaging and Shipping

Products that are ready for delivery are carefully packaged.

Partner with BEO Textile Where Quality Meets Reliability.

With our advanced production infrastructure and experienced team, we offer bespoke solutions for your brand.